Oak Bluffs, MA old classifieds archive and funnies > By Year

> 2006

> Point level measurement - ultrasonic switch

Point level measurement - ultrasonic switch

Point level measurement - Ultrasonic switch

Point level switch Model # 7ML15103JE02

ULS 200, AC Version, Relay, Poly .5 (1/2") NPT conduit / cable conn., NPT PVDF, CE

Polycarbonate, Two 1/2†NPT Electrical Connections (Female threads on unit) ( Thru conn. or Line in, Load out)

The perfect point level backup device for your capacitance applications.

Siemens Milltronic Process Instruments Inc.

The Pointek ULS200 is an ultrasonic non-contacting switch with

two switch points for level detection of bulk solids, liquids and

slurries in a wide variety of industries; ideal for sticky materials

The noncontacting Pointek ULS200 is virtually immune to the problems

inherent to most contacting level detection devices and is unaffected by

the presence of suspended solids in a liquid application.

The ULS200 system combines the sensor and the electronics in a

single, lightweight body. The ultrasonic sensor continuously emits sonic

pulses that are reflected as echoes from the target surface. By measuring

the time delay between transmitted and reflected pulses, the levels at

• 2 switch outputs for high-high, high, low and low-low level

alarms or pump up/pump down control

2 Relay contacts = 5a @250 v , non-inductive spdt contacts

Unit Fused @ .25a, 250v slow blow

• Built-in temperature compensation / Integral temperature compensation

• Electronics provided with fail-safe function

• Threaded and 3A approved sanitary fitting clamp process connections

• Polycarbonate enclosure, Type 6/NEMA 6/IP67

• Easy, two-button programming

• Noncontacting point level detection on bulk solids (0.8 to 9.8 ft.),

liquids and slurries (0.8 to 16.4 ft.)

• Two-button setup, simple cable-entry

wiring, and a self-cleaning sensor

• Power 100 – 230 V ac power supply

• This is the Sanitary version with an industry standard flange

To meet the need for configurations that are effective in standard

processes as well as class/zone approved applications, a chemically-resistant sensor. This extends the unit’susage to chemical, petrochemical and water, and wastewater industries,

where more rigorous approval levels are required.

When compared to other point level detection products, the Pointek

ULS200, with its unique and powerful features, delivers a cost-effective

The measuring range for bulk solids is max. 3 m (9.8 ft) and 5 m

(16.4 ft) for liquids and slurries. Unlike invasive contacting devices,

there is no material buildup on the sensor.

The level switch has a rugged design, combining the transducer

and electronics in one durable device. It has no moving parts

and is virtually maintenance-free.

The transducer, is inert to most chemicals. This means the device can be used in the

chemical, petrochemical, water and wastewater industries. This

sanitary version of the ULS200, with an industry standard flange

is easy to remove from the application for cleaning. It

thus satisfies the prerequisites for use in the food, beverage and

pharmaceutical industries. The Pointek ULS200 delivers superior

performance while reducing maintenance, downtime and

• Key Applications: liquids, slurries, fluid materials, plugged

chute detection, chemical industry

This low-cost ultrasonic point level switch permits non-contacting

detection of two distinct levels of liquids, slurries and bulk

solids. The measuring range for bulk solids is max. 3 m, and 5 m

for liquids and slurries without ever touching the product. Unlike

invasive contacting devices (bubblers, floats), there is no material

The level switch has a rugged design, combining the sensor and

electronics in one compact device. It has no moving parts, and

is virtually maintenance-free.

The transducer is inert to most chemicals. The Pointek ULS 200 delivers superior

performance while reducing maintenance, downtime and

See Chapter 4/4 of Pdf. File below for complete information.

http://www.automation-drives.ru/pi/catalogs/fi01_e_k04.pdf

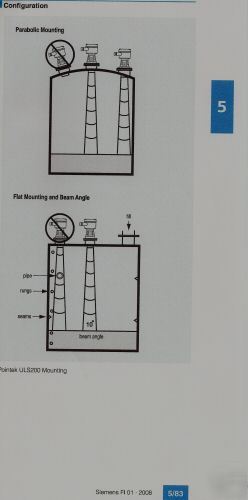

The Pointek ULS200 should be mounted in an area that is within

the temperature range specified and that is suitable to the enclosure

rating and materials of construction. The cover should be

accessible to allow programming, wiring and display viewing.

or current runs, contactors and SCR control drives.

Locate the Pointek ULS200 so that it has a clear sound path perpendicular

to the material surface. The sound path should not intersect

the fill path, rough walls, seams, rungs etc.

Point level measurement - Ultrasonic switch

C) Subject to export regulations AL: N, ECCN: EAR99

Measuring principle Ultrasonic level switch

Measuring range in liquids 0.25 to 5 m (0.8 to 16.4 ft)

Measuring range in bulk solids 0.25 to 3 m (0.8 to 9.8 ft)

• Ambient temperature -40 to +60 °C (-40 to +140 °F)

• If mounted in metal threads -20 to +60 °C (-5 to +140 °F)

• Process pressure 0.5 bar (7.25 psi) max.

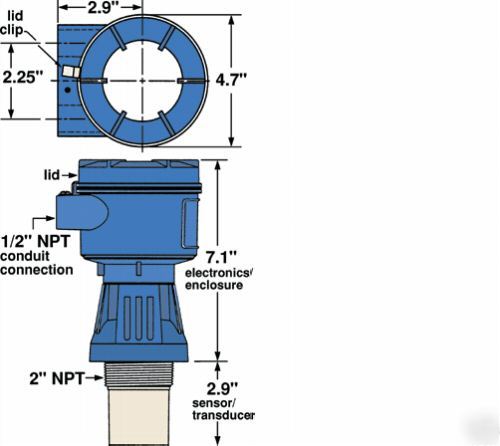

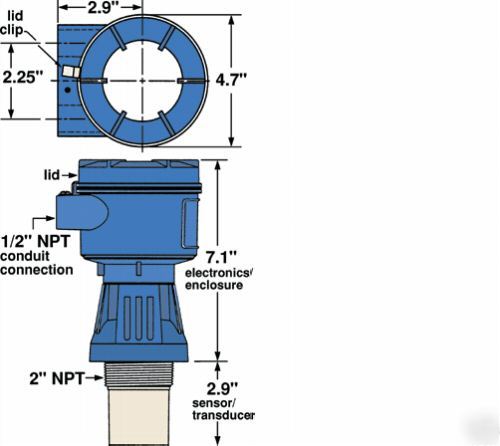

Weight Approx. 1.5 kg (3.3 lbs)

Transducer material PVDF copolymer

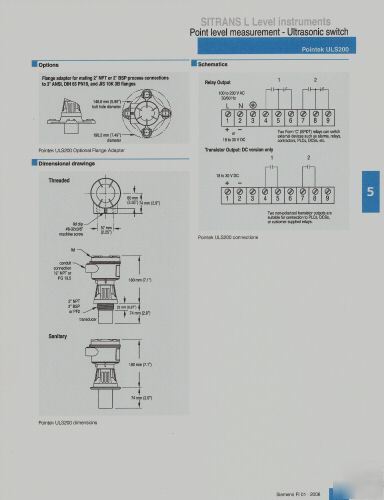

Threaded mounting 2“ NPT [(Taper), ANSI/ASME

or G 2†[(BSPP), EN ISO 228-1]

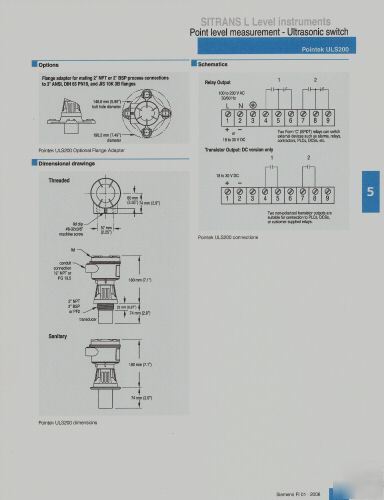

• Optional flange adapter For 3“ ASME, DN 65, PN10 and

JIS 10 K3B can be purchased separately (not included)

Display LCD, three digits, 9 mm (0.35“)

between sensor face and material,

Electronics/enclosure Connection: terminal block, max.

2.5 mm2 (14 AWG) solid/1.5 mm2

Degree of protection IP67/Type 6/NEMA 6

Cable inlet 2 x ½“ NPT or 2 x PG 13.5

Certificates and approvals • CE (EMC certificate available on

CE, ATEX II 2G EEx md IIC T5, SAA1) (Note: Due to

1) Available with enclosure/cable inlet option 4 only

CE, CSA Class I Div. 1, Class II Div. 1, Class III2)

2) Available with enclosure/cable inlet option 4 only and process connection

CE, FM Class I Div. 1, Class II Div. 1, Class III2) G

CE, CSA Class I Div. 2, Class II Div. 23)

3) Available with enclosure/cable inlet options 2 and 4 only

ETFE, 2" NPT [(Taper), ANSI/ASME B1.20.1] A

EFTE, R 2" [(BSPT), EN 10226] B

EFTE, G 2†[(BSPP), EN ISO 228-1] C

PVDF copolymer, 2" NPT [(Taper), ANSI/ASME

PVDF copolymer, R 2" [(BSPT), EN 10226] F

PVDF copolymer, G [(BSPP), EN ISO 228-1] G

PVDF copolymer, 4†sanitary mounting,

4) Available with approval option H only

Tag, stainless steel, 12 x 45 mm (0.47 x 1.77"), one

text line, suitable for enclosures

Universal Box Bracket Mounting Kit 7ML1830-1BK

3†ASME, DN 65, PN 10, JIS 10K 3B ETFE Flange

3†ASME, DN 65, PN 10, JIS 10K 3B ETFE Flange

2" BSPT Locknut, plastic 7ML1830-1DQ

4†sanitary mounting clamp 7ML1830-1BR

7 Non-contacting point level measurement for liquids, slurries

7 Integral temperature compensation

7 2 switch outputs for high-high, high, low and low-low level

7 Electronics provided with fail-safe function

7 Threaded and 3A Tri-clamp process connections

7 Polycarbonate or aluminium enclosures, IP 67 / Type 6 /

7 Easy, two-button programming

7 Simple installation and maintenance

• Measuring principle Ultrasonic level switch

Measuring range in bulk solids

2 changeover contacts, rated 5 A

- Transmission angle See transducers on page 4/48 ff.

- 40 to +60 °C (-40 to +140 °F)

- 20 to +60 °C (-5 to +140 °F)

• Degree of protection IP 67 / NEMA 6 / Type 6

• Process pressure 0 bar (normal atmospheric pressure)

Material Polycarbonate or epoxy-coated

Transducer material Tefzel® or Kynar Flex®

Sanitary mounting 4" Tri-clamp fitting according to

AC 100 to 230 V, 15%, 50/60 Hz,

Display LCD, three digits, 9 mm (0.35")

between sensor face and material,

Electronics/enclosure Connection: terminal block,

Degree of protection IP 67 / Type 6 / NEMA 6

Cable inlet 2 x 1/2" NPT, or 2 x PG 13.5

Certificates and approvals • CE1), CSANRTL/C, FM, 3A

Installation Couldn’t be Simpler

Just mount the compact Pointek ULS200 unit on the top of the vessel

with a standard 2†fitting, connect it to the appropriate AC power

supply, set detection levels using the two built-in programming keys.

That’s it! No need to shut down the process or fill/empty the vessel. The

sanitary model is easy to remove and clean — a key requirement for

food and beverage processes.The Pointek ULS 200 should be mounted in an area that is within

the temperature range specified and that is suitable to the hous-

ing rating and materials of construction. The cover should be

accessible to allow programming, wiring and display viewing.

or current runs, contactors and SCR control drives.

Locate the Pointek ULS 200 so that it has a clear sound path perpendicular

to the material surface. The sound path should not

intersect the fill path, rough walls, seams, rungs, etc.

The Pointek ULS 200 is available in three thread types: 2" NPT,

2" BSP or PF2 and can be fitted with the optional 75 mm (3")

flange adapter for mating to 3" ANSI, DIN 65, PN10 and

Separate cables and conduits may be required to conform to

standard instrumentation wiring or electrical codes.

You can use your Pointek ULS200 as a high-level

It’s a good engineering practice to have a backup highlevel

switch that uses a different technology than your

Look at all the ULS200 offers...

• Two independent settings that allow for high- and lowlevel

switch points from a single unit

• Noncontacting, self-cleaning sensor, made of Tefzel®

• Polycarbonate or Epoxy enclosure available

Zone 1, Class II Div. 1, Class III

(only with housing option 4 and

Zone 1, Class II Div. 1, Class III

This Item Cost new = $700 + 200 (AC version)

Not Included # 7ML1998-1XB81 CD Manual

manual CD containing the complete ATEX Quick Start and instruction manual library. But….. Here’s the same info on Pdf.

http:// /unleashd/catalog/sensors/7ML19981AS01.pdf

https://pia.khe.siemens.com/efiles/instrumentation/catalogs/fi01/fi01_en_extract/sitransl_pointekuls200_fi01en.pdf

OR Contact SMPI Technical Publications at the following address:

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.****@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select Level

Measurement and then go to the manual archive listed under the product family.

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select Continuous

Weighing Systems and then go to the manual archive listed under the product family.